Let’s be real here- furnishing your home can get to be expensive. To help with the cost I try to prioritize what I spend my money on and what I can DIY.

I had been searching for a headboard for our bedroom for months with no luck. Eventually I stumbled upon one that I fell in love with from Magnolia. The only problem? It was over $1000 dollars. While some of you might be willing to pay, I knew that it wasn’t something I was willing to splurge on. So instead I decided that I was going to try and recreate it myself.

In this post I’ll walk you through how I created a similar version of a herringbone pattern headboard for a much lower price.

*Side note: The specific dimensions I will be mentioning in this post are suitable for a queen size bed. However, they can totally be customized depending on your bed size.

SUPPLIES/TOOLS NEEDED:

- (4) 1/2in 2x4ft plywood sheets

- (4) 2×2 8ft pine boards

- (3) 1 x 4 common boards

- Edge banding ~7 packs

- Iron

- Foam roller

- Sanding block- 180 & 220

- Wood glue

- Wood conditioner

- Wood stain of choice

- White wash (optional)

- Polyurethane

- 1inch 25mm pocket screws

- 1inch brad nails

- 1 1/2inch brad nails

- Kreg jig

- Dowel jig

- Clamps

- Drill

- Table saw

- Miter saw (optional)

- Braid nailer

- Router

- Router table

- Scissors

- Measuring Tape

- Pencil

SHOP SUPPLIES/TOOLS HERE:

Step One: Create your Dimensions

If you are creating your headboard for a queen size bed the dimensions that you’ll need will be listed throughout this post. So feel free to skip this step as I am providing this information to you.

Otherwise, you will first have to figure out what dimensions you will need.

Whenever I am considering purchasing a piece of furniture (or in this case building), I love using painters tape to map out the dimensions. I am a very visual person so this allows me to see if the piece of furniture will look proportional in regards to the size of my room.

Play around with your dimensions and jot down your measurements once you find ones that you like.

Step Two: Cut plywood to size

You will need a total of (4) 1/2in 2 x 4 ft plywood sheets to create the face of the headboard. For a queen size bed each plywood sheet should be cut down to measure 16 1/2in wide x 40in tall.

I recommend a table saw to trim your plywood, but a circular saw will work just as well.

Step Three: Create pocket holes

Pocket holes and screws will be what attach and hold all 4 of the plywood sheets together.

Using your kreg jig, make 7-8 pocket holes on the back side of each plywood sheet (3-4 on each end). The image below will show you placement of each pocket hole.

If you are unfamiliar with how to use a kreg jig, this video that I found on Youtube provides a great summary on how to use this tool.

*Side note: I highly recommend doing this step before the edge banding. You are able to do it afterwards but since the edge banding is so delicate, I found that the pressure from the Kreg Jig can cause some damage to the edge banding.

Step Four: Veneer edge banding

Now here’s where the fun begins. Veneer edge banding is a thin wood-like material used to cover raw edges of plywood. For this project we are not using it to conceal raw edges, but instead to create a herringbone pattern on the face of the headboard.

The back-side of the edge banding contains adhesive that is heat-activated so you’ll need an iron for application. Additionally, you’ll need scissors to trim the edge banding and a roller or a wood block to apply pressure.

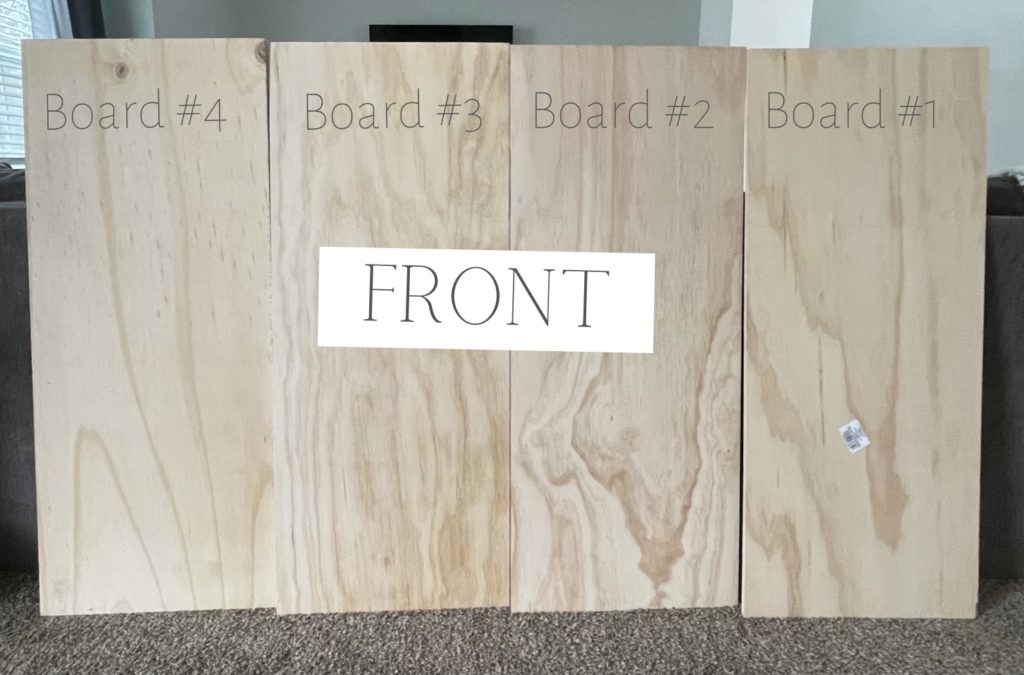

Before getting started with this step it is helpful to label the back of each board 1-4 to ensure that they stay in order and to avoid applying the pattern in the wrong direction.

Take board #1 and line a strip of edge banding beginning at the top left corner. Bring it down diagonally to the right side of the board. Be sure to leave an etxra 1/2in-1in of material on each end (you’ll see why later on in the post).

Set your iron to the “cotton” setting and firmly press onto the edge banding until the adhesive has melted. To ensure that the banding remains in place use a roller or a wood block to apply additional pressure.

Continue until your board is completely covered with the veneer edge banding.

Repeat these steps for board #3.

For boards #2 and #4 the same steps will be applied, however instead of starting at the top left corner, you will start at the top right corner.

*Side note: If for whatever reason you mess up and need to remove an edge banding piece all you have to do is re-apply heat over it and it should come right off.

Once you finish edge banding an entire board it will look like the bottom half of this board (I had already trimmed the edge banding on the top half)

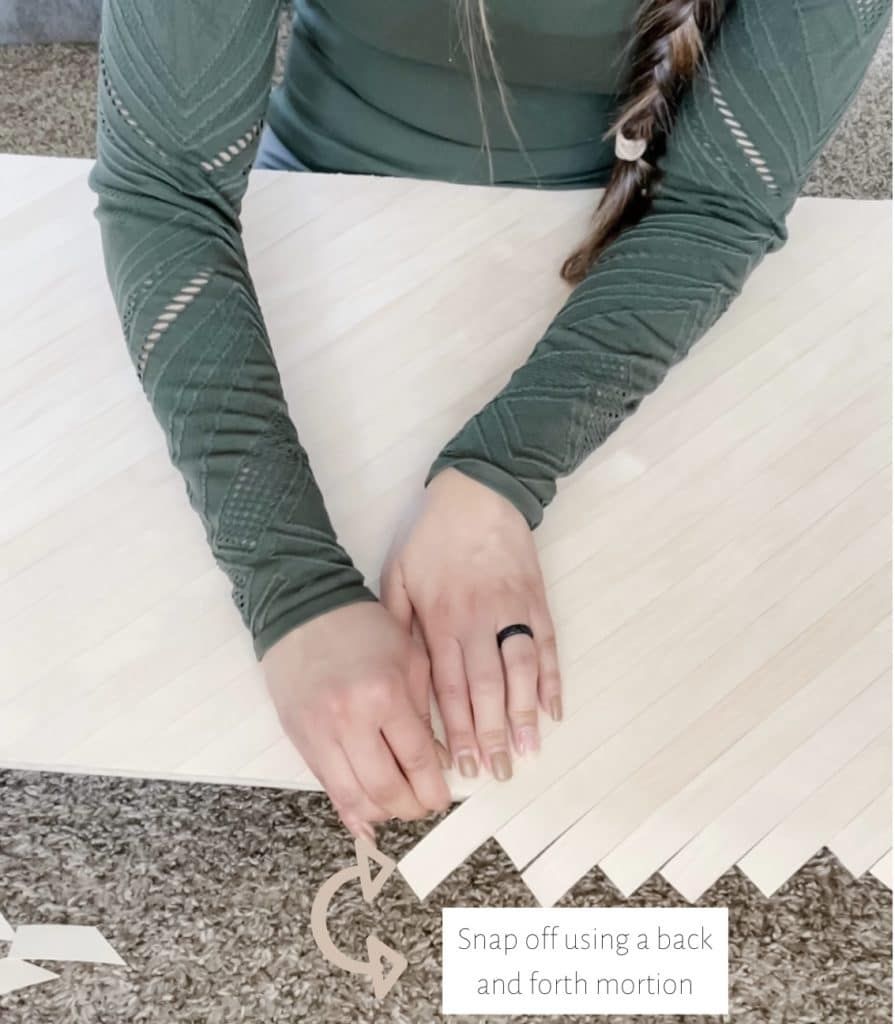

Now I’m sure you can find several ways to trim off the excess edge banding. I tried several different methods, but I found that the easiest way was to just snap it off.

Apply some pressure over the banding strip with one hand. Use your opposite hand to gently bend the strip downwards, followed by gently bending it upwards. Keep repeating until the banding snaps off.

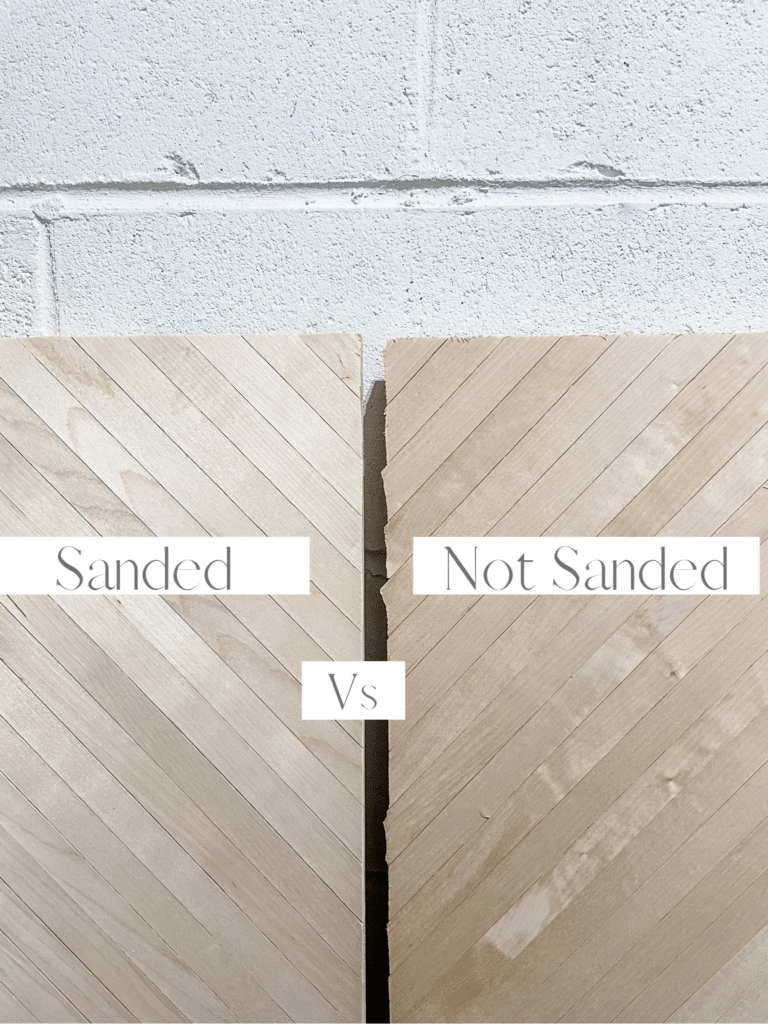

As you’re snapping off the edge banding you’ll notice that the edges will become frayed- that’s where sanding will come into play.

I suggest using an 180 grit sanding sponge followed by a 220 grit to sand down the edges. Make sure that you are gentle during this step as you don’t want to accidentally pop off a piece of the edge banding. I also suggest going in an “up and down” or “side to side” direction rather than a “back and forth” motion to avoid pressure against the banding.

If there are still pieces left behind that are too big to be sanded down, use a precision knife to gently cut down those chunks.

As you probably figured by now, this is why I decided to purchase 4 separate sheets of plywood vs 1 larger one. This pattern would have been more complicated to create and trim if it were all on one board.

Step 5: Assemble boards together

This is when your pieces of wood will finally start to look like a headboard!

Flip all four of the boards so that the edge banding pattern is face down. Double-check to make sure they are all in order and that the pattern is facing in the correct direction.

Start by taking board #1 and board #2 and line them up directly next to each other. Take one of the boards and add a thin layer of wood glue along the inner edge of the board. Clamp both pieces of wood together (using clamps is optional but I highly recommend them in order to create a tight and secure fit). Attach them together using 1in 25mm coarse pocket screws and the pocket holes that you created early on.

*Side note: Before attaching your pocket screws, double-check to make sure that your boards are level and flush to each other.

Repeat for boards #3 and #4.

Once you have your two halves ready all that’s left to do is to attach them at the middle. Bring the two halves together side by side. Place a thin layer of wood glue along the inner edge of one of the halves.

Chances are that you probably don’t have clamps big enough to clamp all of the boards together at once -and quite frankly I don’t think its worth spending money on buying some when you are likely not going to use them often. Instead, line your boards directly next to a wall (or a couch like I did) and use that as resistance when drilling your screws in. If possible have an extra set of hands to help and apply pressure on the far end of the boards towards the wall.

Step 6: Add additional support

The plywood pieces should feel pretty sturdy once they are all attached together. However, since plywood is generally thin I attached (3) 1×4’s on the backside of the board for additional structural support.

Add a layer of wood glue onto the 1×4’s and firmly press down. You can place weights on top of the 1×4’s while the glue dries.

Secure the 1×4’s onto the plywood using a brad nailer with 1inch brad nails so that they don’t puncture through the plywood.

Step 7: Cut out frame

Using your miter saw or table saw, cut the 2×2’s to size.

Cut 2 of them to measure 58in in length. These will be your side posts.

Cut the other 2 pieces to measure 66in in length. These will be your top and bottom piece.

*Side note: It is important that when purchasing your lumber you get pieces that are as straight as possible so that they sit flush against the plywood. As you can see in this example, the 2×2’s in the middle are straight unlike the two outer pieces. I ended up going back to the store and exchanging them for better pieces.

Step 8: Sand & stain

Feel free to assemble the headboard together first before staining, I personally just find it easier to prep and stain the wood beforehand.

Use an orbital sander to sand the 2×2’s. Start off with 80 grit followed by 120 grit.

Use an 80 & 120 grit sanding sponge to sand the face of the edge banding. Again, you want to make sure that you are extremely careful when doing so, as you don’t want to accidentally chip off any pieces of edge banding.

Apply wood conditioner followed by stain of choice.

Step 9: Assemble frame

Run the top and bottom pieces through a table router to create a groove within them. This will allow for them to slide right into the plywood. I suggest making the groove about 3/4in deep and I used a 1/2in router bit to do so.

Use a dowel jig to drill a hole into the center of both ends of the top post piece. Drill a hole into the inner sides of the two side posts to line up with the top post holes created. Ensure that holes are big enough for a 3/8in (10mm) dowel to fit.

Add a layer of wood glue on the top edge of the plywood and slide the top 2×2 piece through.

Repeat for the bottom piece.

Use a brad nailer and 1 1/2in nails to secure the posts into the plywood.

Add wood glue into the previous holes drilled for the dowels. Insert dowel and connect the top and side posts together.

Secure the side posts onto the plywood using pocket screws and the holes drilled early on.

Step 10: Fill gaps & seal

Once the frame is assembled, check for areas that may need any touch-ups.

In my case my top and bottom posts were cut a tad bit too short so they were not sitting flush against the side posts. To fix this, I simply went in with tinted wood filler (since my wood was already stained) to close any gaps.

Seal the headboard using your polyurethane of choice to prevent any stains or scratches.

To my surprise this headboard came out exactly how I pictured it in my mind! I love how subtle the herringbone pattern is, yet still unique. Let me know what you think of it in the comments down below.

If you would like to see this project in action, check out @ourblissfulnest on Instagram. There you can find a saved highlight titled “DIY Headboard” where you can see step-by-step video progress. As always if you decide to try and recreate this project feel free to tag @ourblissfulnest on your post or send me a picture via DM or email. I would love to see how it turns out!

Disclaimer: This post contains links in which I do earn a small commission from if you decide to purchase through them. This comes at no additional cost to you and as always your support is greatly appreciated!